Martínez Heavy Equipment

Replaced tribal knowledge and spreadsheet-based tracking with a structured fleet management platform that eliminated double-booking and cut equipment downtime by 45%.

Equipment allocation depended on one person's memory and scattered spreadsheets.

Centralized fleet platform with real-time utilization tracking and predictive maintenance scheduling.

Operational Context

Martínez Heavy Equipment manages a fleet of over 40 pieces of heavy equipment deployed across 12 active construction project sites. The fleet manager relied on personal knowledge and a complex spreadsheet to track which equipment was where, what needed maintenance, and what was available. As the company grew from 5 to 12 sites, this approach broke down. Double-bookings became weekly occurrences and unexpected breakdowns caused cascading project delays.

Structural Problem

Symptoms

- Equipment double-booked across project sites weekly

- No visibility into current equipment location or utilization rates

- Maintenance performed reactively: breakdowns caused unplanned project delays

- Fleet manager was single point of failure for all allocation decisions

- Project managers couldn't request equipment without calling the fleet manager directly

- No historical data on equipment performance or cost per project

Root Causes

- Resource allocation was based on tribal knowledge rather than a structured tracking system

- No separation between equipment scheduling, maintenance planning, and project management

- Scaling was blocked by operational bottleneck: one person held all fleet knowledge

Intervention

We architected and deployed a fleet management platform that gave every stakeholder, from project managers to the fleet manager to leadership, real-time visibility into equipment status, location, and availability. The system introduced structured workflows for equipment requests, maintenance scheduling, and utilization reporting.

What Changed

- Moved from personal-knowledge-based allocation to a request-and-approve workflow

- Separated equipment scheduling from maintenance planning into distinct but connected modules

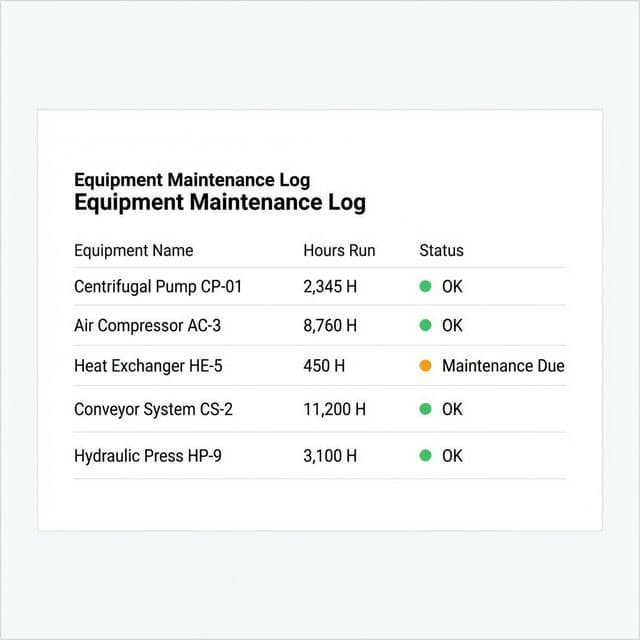

- Introduced preventive maintenance triggers based on usage hours and calendar intervals

- Created project-level cost tracking for equipment usage

- Established clear escalation paths for equipment conflicts between projects

What We Implemented

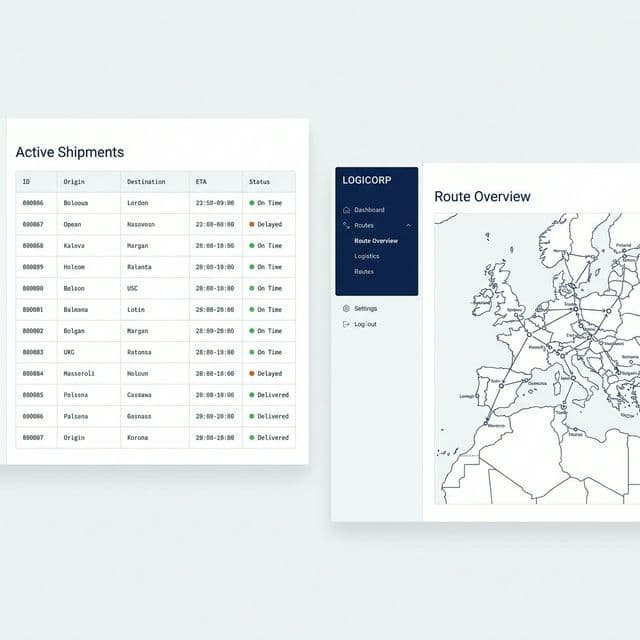

- Fleet dashboard with real-time equipment status across all project sites

- Equipment request and approval workflow for project managers

- Maintenance scheduling module with automated reminders and history tracking

- Utilization analytics with cost allocation per project

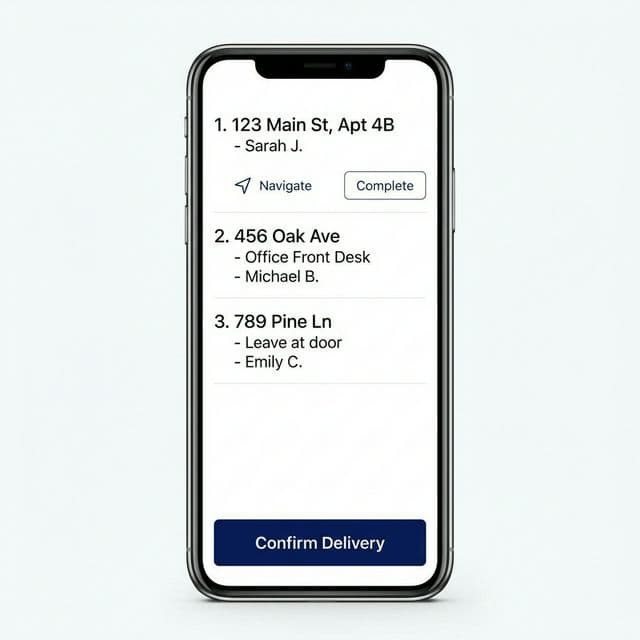

- Mobile check-in/check-out system for equipment at project sites

- Conflict detection that flags double-bookings before they happen

- Monthly fleet performance report with cost and utilization trends

- Role-based access for fleet managers, project managers, and executives

Operational System Modules

These modules were implemented to support the operational architecture and restore visibility, control, and accountability.

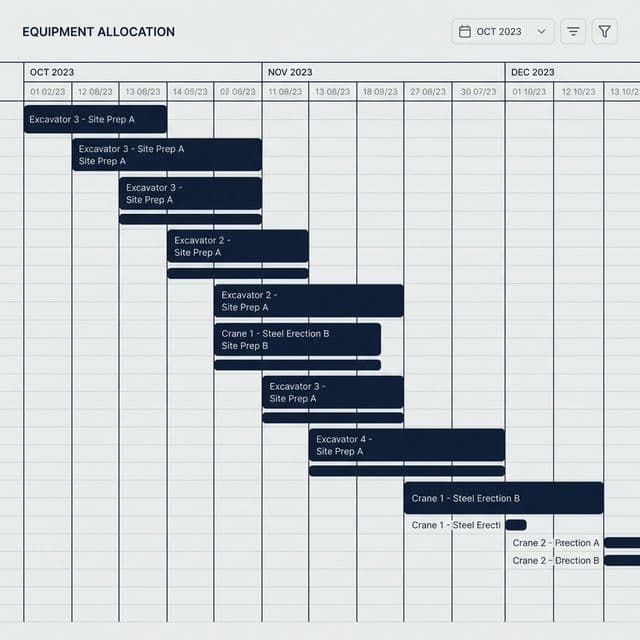

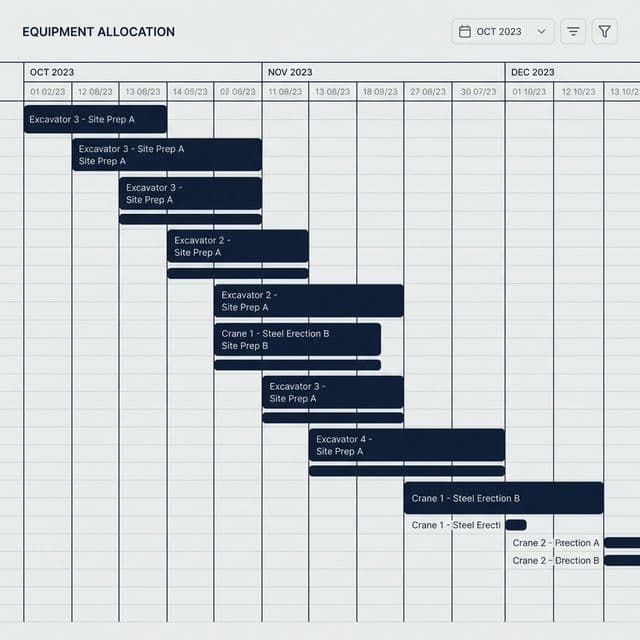

Allocation Gantt Chart

Visual conflict detection for equipment scheduling.

Maintenance Tracker

Usage-based preventive maintenance scheduling.

Site Check-In Kiosk

Tablet interface for site supervisors to accept equipment.

Cost Analytics

Project-level cost attribution for all equipment usage.

Request Portal

Streamlined equipment request form for project managers.

Governance & Stabilization

Operational Cadence

- Daily equipment status sync: automated report to fleet manager at 6:00 AM

- Weekly fleet review with project managers to anticipate upcoming needs

- Bi-weekly maintenance review to track preventive vs reactive ratio

- Monthly executive report on fleet utilization, cost, and downtime trends

- Quarterly capital planning review using historical utilization data

Accountability Structure

- Project managers own equipment requests: must submit 48 hours in advance

- Fleet manager approves allocations and owns conflict resolution

- Site supervisors responsible for daily check-in/check-out confirmations

- Maintenance team owns preventive maintenance completion within scheduled windows

- Operations director reviews monthly fleet cost vs budget

Outcomes

- Fleet manager is no longer the single point of failure: any trained staff can manage allocations

- Project managers can self-serve equipment requests without phone calls

- Leadership has cost visibility per project for the first time

- Maintenance team shifted from reactive to 80% preventive maintenance

- Company confidently took on 3 new project sites within 6 months of deployment

- Equipment purchasing decisions now based on utilization data rather than gut feel

The Solution Behind This Result

Related Solution

Product & Scale Infrastructure

Scalable platforms and structured expansion for sustainable growth.

Explore This SolutionExplore Further

Toxios Transformation Framework™

Explore the four-layer methodology behind every transformation we implement.

Learn MoreTake the Free Diagnostic

Identify your operational maturity level and the highest-impact changes for your business.

Learn More